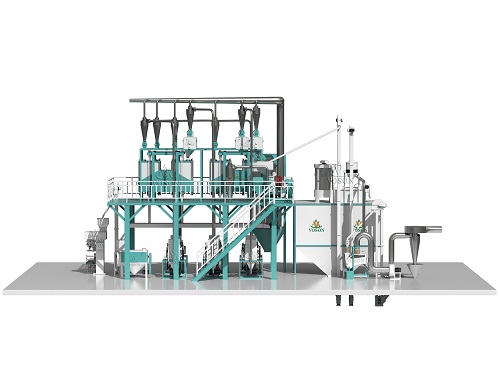

20TPD Wheat Flour Milling Project

The 20TPD wheat flour milling project was designed and manufactured by Henan Voson Grain Engineering Machinery Co., Ltd., a leading company in the field of flour milling equipment. 20t wheat flour milling plant represents a cost-effective entry-level solution for investors who want to establish or expand a flour milling business with moderate capacity.

Unlike standard models on the market, Voson integrates advanced cleaning, conditioning, milling, and packaging technologies into a compact system. Voson has successfully exported and installed similar 20TPD lines in Africa, Southeast Asia, and the Middle East, where stable flour quality and easy operation are critical for local investors.

Wheat Flour Milling Process Flow

The 20T wheat flour milling process is carefully engineered to maintain efficiency and consistent product quality.

- Cleaning Section – Wheat is passed through vibrating screens and destoners to remove stones, dust, and other impurities.

- Conditioning Section – Moisture adjustment improves the milling performance and extends the service life of the rollers.

- Milling Section – High-precision roller mills grind the conditioned wheat, separating flour, bran, and germ with minimal waste.

- Sifting Section – Plansifters ensure uniform flour granularity and stable extraction rates.

- Packaging Section – Automatic weighing and packing equipment guarantees accurate and hygienic bagging of flour and bran.

This scientific workflow ensures that the final flour meets both industrial and household consumption standards.

Technical Parameters of 20TPD Wheat Milling Plant

| Capacity | Final Products | Flour Extraction | Power Requirement | Floor Area |

|---|---|---|---|---|

| 20 TPD | High-grade flour, bran | 72–75% | Approx. 60–70 kW | About 120–150 m² |

It should be noted that there will be some differences in the equipment of the 20t flour mill for processing wheat seeds. When you consult, our technicians will confirm your raw materials and requirements. See more details below, you are also welcome to customize your wheat flour mill plant.

Video for 20T Wheat Flour Milling

Key Features and Advantages of Voson Wheat Flour Milling Line

Proven Engineering Experience – Voson’s design team has decades of expertise in building turnkey flour milling plants worldwide.

Compact and Efficient Layout – The plant requires limited installation space while maintaining stable production capacity.

Energy-Saving Design – Optimized power distribution reduces long-term operational costs.

Reliable and Durable Equipment – Core components are manufactured under strict quality control, ensuring long service life.

Easy Operation and Maintenance – User-friendly control systems and clear process design reduce training requirements for operators.

Adaptable to Local Conditions – Voson engineers customize the configuration according to different raw materials, climates, and market demands.

Conclusion

The 20TPD wheat flour milling plant by Voson is more than just a set of machines; it is a complete solution that combines advanced technology, compact design, and practical engineering experience. Many international clients have chosen this model as the first step to enter the flour production industry, thanks to its reliability and cost-effectiveness. With Voson’s professional support in design, installation, and after-sales service, investors can confidently build a sustainable flour milling business.