Peanut Oil Production Project

Voson Machinery specializes in designing and delivering complete peanut oil production line that combine high efficiency, advanced technology, and consistent product quality. From seed cleaning and shelling to pressing and refining, every stage is engineered for optimal oil recovery and smooth plant operation. Our turnkey solutions cater to small artisanal setups as well as large industrial plants, providing investors with reliable, scalable, and cost-effective projects.

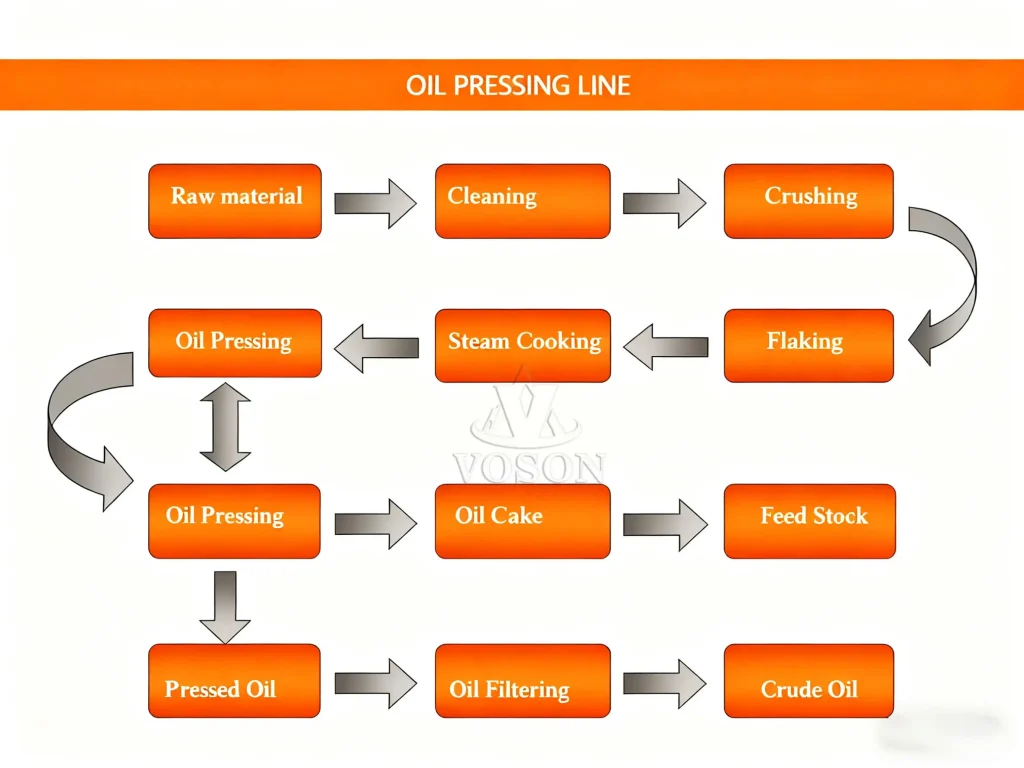

Process Flow of Peanut Oil Production Line

Cleaning and Destoning

Raw peanuts are thoroughly cleaned using vibrating screens and destoners to remove dust, stones, and foreign materials, ensuring the raw material is ready for processing.

Shelling and Optional Roasting

Peanuts are mechanically shelled to separate kernels from shells. For high-aroma edible oil, controlled roasting can be applied before pressing to enhance flavor and yield.

Crushing and Flaking

Shelled peanuts are crushed into smaller particles and flaked into thin layers, which facilitates efficient oil extraction.

Oil Extraction

Voson offers both mechanical screw pressing and hydraulic pressing for different production scales. For large-scale projects, solvent extraction can be added to maximize oil yield.

Filtration and Refining

The crude peanut oil is clarified and refined through degumming, neutralization, bleaching, and deodorization, ensuring it meets international edible oil standards.

Storage and Packaging

Refined peanut oil is transferred to stainless steel storage tanks and packaged into bottles, cans, or bulk containers, ready for domestic distribution or export.

Technical Parameters (Example: 50TPD Peanut Oil Production Line)

| Item | Specification |

|---|---|

| Capacity | 50 tons peanuts per day |

| Oil Yield | 45%–50% depending on peanut variety and processing method |

| Main Equipment | Vibrating cleaner, destoner, sheller, roaster, crusher, flaker, screw/hydraulic press, plate frame filter, refining system |

| Power Requirement | 220–270 kW |

| Plant Area | 1,500–2,000 m² |

| Operation Mode | Continuous, PLC-controlled automation |

Voson peanut oil production lines are ideal for regions with plentiful peanut cultivation such as China, India, Nigeria, Sudan, and East Africa. Our engineering team adapts each project to local conditions including raw material characteristics, energy supply, labor skills, and market demand.

Key Advantages of Voson Peanut Oil Projects

Turnkey Engineering Solutions – from design to commissioning, including training and after-sales support.

Optimized Oil Yield – precision shelling, crushing, and pressing methods ensure maximum extraction.

Scalable Design – capable of supporting 10TPD to 500TPD production lines.

Energy-Efficient Operations – advanced equipment reduces operational costs.

Proven Track Record – successful projects delivered in Asia and Africa demonstrate reliability.