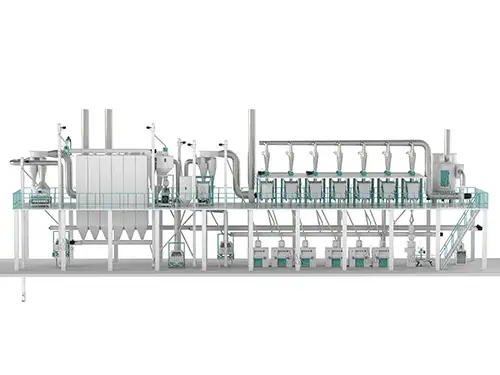

100TPD Maize Milling Project

The 100TPD maize milling project is designed for regional flour production centers that supply urban and semi-urban markets. Compared to small and medium-sized lines, the 100-ton capacity offers a balance between large-scale industrial output and operational flexibility. This project is ideal for investors who aim to serve bakeries, food manufacturers, and wholesale distributors with consistent quality maize flour and grits.

Voson has equipped this line with advanced cleaning, conditioning, milling, and packaging systems, combined with centralized control. The plant ensures stable production, high extraction rate, and long-term reliability while meeting international food safety standards.

100TPD Maize Milling Plant Process Flow

The 100tpd maize milling project is a complete dry method maize processing line, designed to produce high-quality maize flour with consistent granularity. The process integrates advanced cleaning, dehulling, milling, and sifting technologies, ensuring both efficiency and product quality.

1. Cleaning and Destoning

Raw maize kernels are passed through a vibrating cleaner and destoner to remove dust, stones, sand, and other impurities. Only clean maize enters the next stages, protecting downstream equipment and improving flour quality.

2. Dehulling and Degermination

The cleaned maize is processed by a dehuller and degerminator, which remove the outer husk and maize germ. This step ensures fine maize flour with lighter color, longer shelf life, and better taste.

3. Conditioning and Milling

The dehulled maize is slightly moistened for conditioning, then fed into high-efficiency roller mills. Multiple stages of grinding and extraction produce grits and fine flour. Voson’s precision milling system minimizes energy consumption while maximizing yield.

4. Sifting and Grading

Ground maize is sifted using multi-layer plansifters to separate flour, grits, and bran. Different mesh sizes ensure accurate classification for market demands.

5. Blending and Packaging

Final products are blended and packed with automatic scales into 1–50kg bags, suitable for retail or bulk supply.

Technical Parameters of Commercial Maize Milling Machine

| Capacity | Extraction Rate | Power Requirement | Land Area | Automation |

|---|---|---|---|---|

| 100TPD | 72–75% | 250–280 kW | 700–900 m² | PLC + Central Control |

Video of 100T Compact Maize Milling Plant

The 100TPD maize milling plant is widely used in regions where maize is a staple food. In East and Southern Africa, this capacity is ideal for supplying regional cities and towns. In Latin America, it meets growing demand for maize-based food industries such as tortillas and snacks. In Southeast Asia, it is applied for both household consumption and food-processing industries. Voson maize milling equipment ensures high extraction rates and consistent quality, making it popular among medium and large-scale investors.

Types of Maize Flour Produced by Voson Equipment

1、Super fine maize flour for bread, noodles, and snacks

2、Maize grits for brewing and food processing industries

3、Regular maize flour for household consumption

4、Bran and germ as by-products for animal feed

Key Advantages of Voson Maize Milling Equipment (100TPD)

Balanced production scale – suitable for regional distribution and industrial manufacturers

Advanced dry milling technology – efficient bran and germ removal, producing fine, white maize flour

Automation and energy efficiency – PLC control reduces manual operation and optimizes power usage

Product versatility – can produce flour, grits, and by-products for multiple market needs

Easy maintenance – modular design and standardized components ensure stable operation