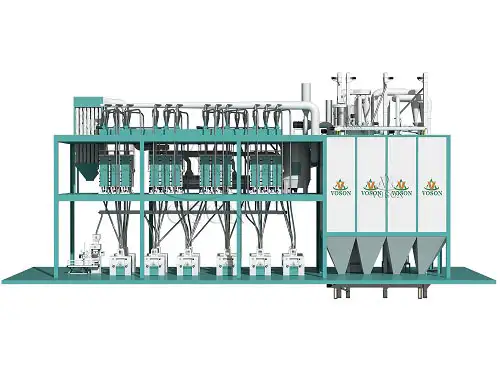

160TPD Wheat Flour Milling Project

The 160TPD wheat flour milling plant by Voson is a turnkey solution for medium to large-scale flour production. Built for stable operation and high extraction rates, it meets the needs of commercial flour producers seeking consistent quality and reliable performance. Voson provides comprehensive services including design, equipment manufacturing, installation, commissioning, and staff training to ensure every project runs smoothly.

Technical Parameters of 160TPD Wheat Milling Plant

| Capacity | Final Products | Flour Extraction | Power Requirement | Floor Area |

|---|---|---|---|---|

| 160 TPD | High-grade flour, bran | 72–75% | Approx. 350–380 kW | About 650–700 m² |

Note: The above parameters are for reference. Actual figures may vary depending on design, configuration, and raw material conditions.

Key Features and Advantages

Stable Operation & Medium-Large Capacity – reliable for commercial production

Double-Ended Roller Mill – high precision, efficient flour and bran separation

Energy Efficient – optimized power consumption reduces operating costs

Advanced Automation – PLC control simplifies operation and lowers labor requirements

Durable Equipment – long service life under strict quality control

Turnkey Support by Voson – design, installation, commissioning, and training ensure project success

Wheat Flour Milling Process Flow – Voson’s Expertise

At Voson, every milling line reflects our decades of experience. In this 160TPD plant, the process begins with the cleaning section, where advanced aspiration systems remove coarse, medium, and fine impurities. This not only prepares the wheat for efficient milling but also keeps the working environment clean and protects equipment longevity.

Next, the wheat enters the conditioning section, where moisture and hardness are carefully adjusted. This step ensures the Double-Ended Roller Mills operate efficiently, providing consistent flour extraction while optimizing energy use and reducing wear.

The milling section is the heart of the plant. Voson’s Double-Ended Roller Mills separate flour and bran with precision, delivering uniform particle size and high-quality flour. This design guarantees stable performance for medium-large capacity production and supports multiple flour grades.

After milling, the flour passes through multi-layer plansifters in the sifting and grading section, separating it into all-purpose, bread, cake, and whole wheat flour.

Finally, the packaging section ensures accurate weighing and hygienic bagging, preserving flour quality from plant to market. Every stage demonstrates Voson’s commitment to reliability, efficiency, and customer satisfaction.

Types of Wheat Flour Can Be Processed

- All-purpose flour – versatile for household and bakery use

- Bread flour – high gluten content for bread, buns, and noodles

- Cake and pastry flour – fine texture, low protein for cakes and pastries

- Whole wheat flour – rich in bran and germ for health-conscious products

Voson can adjust milling configurations and extraction ratios to suit market demands.