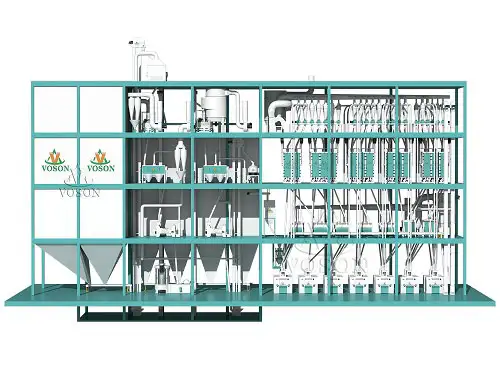

200TPD Wheat Flour Milling Project

The 200TPD wheat flour milling project designed and supplied by Voson represents a new generation of large-scale grain processing facilities. With a capacity of 200 tons per day, this project goes beyond traditional milling by integrating advanced automation, real-time monitoring, and intelligent control systems. The result is a plant that reduces labor demand, enhances production stability, and ensures consistent flour quality for industrial bakeries, food producers, and international distributors.

Process Flow – Controlled by Automation

Instead of relying solely on operator experience, the 200TPD plant is managed through a centralized PLC and SCADA control system. Every stage of the process is supervised digitally, minimizing human error and maximizing precision.

Cleaning & Pre-treatment:

The raw wheat passes through cleaning machines equipped with dust removal and aspiration systems. Operators can track performance from the control room, ensuring a hygienic, dust-free environment.

Conditioning:

Moisture levels are automatically adjusted through intelligent sensors. The system maintains the ideal balance, optimizing the tempering time without manual intervention.

Grinding & Milling:

Double-Ended Roller Mills are operated under automated settings, which adjust the roller pressure and gap in real time. This maintains high flour extraction rates while protecting product consistency.

Sifting & Classification:

High-capacity plansifters work in combination with electronic monitoring. Alerts are triggered immediately if any abnormal vibration or output variation occurs.

Packaging & Storage:

Flour is packed via fully automated weighing and bagging machines. Data on daily output, bag counts, and storage inventory are sent directly to the central control system, allowing for smart logistics planning.

The 100-300ton/d wheat flour milling plant is a kind of multistory type seeds milling line. It consists of high square plansifter, pneumatic flour mill machine, purifier, etc. to realize advanced flour milling technology. It usually needs 4-6 floors (also can be designed into a steel structure) for installing the complete wheat flour plant. The whole plant is durable to use, easy to operate and maintain, and has high productivity and flour extraction rate. Therefore, this wheat flour mill plant can be used to produce different grade wheat flour as well as special flour.

Concrete structure building flour mill plant usually has three configuration design: four-story building, five-story building and six-story building. It can be determined according to the customer's requirements.

Technical Parameters

| Parameter | Value |

|---|---|

| Processing Capacity | 200 tons per day |

| Final Products | High-quality wheat flour, bran |

| Flour Extraction | 75%–80% (adjustable by demand) |

| Power Requirement | Approx. 650–700 kW |

| Land Area | About 5,500–6,000 m² |

Note: The above values are reference parameters. Final design may vary according to specific wheat quality and plant configuration.

Key Features & Advantages Voson Wheat flour Mill Line

Full Automation – Centralized PLC & SCADA systems minimize manual operation.

Higher Efficiency – Consistent production with real-time data monitoring.

Stable Quality – Automated roller gap adjustment ensures uniform flour.

Lower Labor Costs – Fewer operators required compared to conventional plants.

Smart Maintenance – Predictive alerts for equipment wear and performance drops.

Voson Turnkey Support – From design and manufacturing to installation and training, clients receive an end-to-end solution.

Types of Flour Produced

The 200TPD plant can deliver a wide variety of flour products to match diverse market needs, including:

- All-purpose flour for household use and general baking.

- Bread flour with higher gluten strength.

- Cake and biscuit flour with lower protein content.

- Whole wheat flour for health-focused markets.

Voson’s intelligent systems allow easy adjustment of flour grades without interrupting production.

The 200TPD wheat flour milling project reflects Voson’s vision of combining large-scale capacity with intelligent automation. It is more than just a flour mill—it is a digitalized factory, ready for clients aiming to supply modern markets with efficiency, consistency, and reliability.