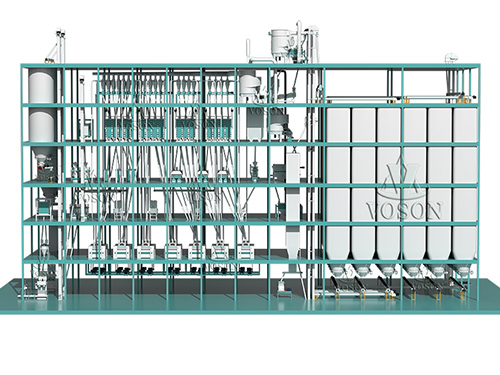

300TPD Wheat Flour Milling Project

The 300TPD wheat flour milling plant by Voson is a high-capacity industrial solution designed for large-scale flour production. With a daily throughput of 300 tons of wheat, this plant caters to enterprises aiming for maximum efficiency while maintaining consistent flour quality. Voson’s engineering expertise ensures the plant is fully automated, energy-efficient, and adaptable to different wheat varieties and local conditions.

The 100-300ton/d wheat flour milling plant is a kind of multistory type seeds milling line. It consists of high square plansifter, pneumatic flour mill machine, purifier, etc. to realize advanced flour milling technology. It usually needs 4-6 floors (also can be designed into a steel structure) for installing the complete wheat flour plant. The whole plant is durable to use, easy to operate and maintain, and has high productivity and flour extraction rate. Therefore, this wheat flour mill plant can be used to produce different grade wheat flour as well as special flour.

Technical Parameters of Voson 300TPD Wheat Milling Equipment

| Production Capacity | Extraction Rate | Power Requirement | Land Area | Automation |

|---|---|---|---|---|

| 300 tons/day | 70–75% | 800–900 kWh/t | 5,500–6,000 m² | PLC/SCADA centralized control |

Key Features and Advantages of Voson 300TPD Plant

High-Capacity Design – Handles 300 tons/day while maintaining stable output.

Parallel Cleaning & Milling – Multi-channel operation reduces downtime and increases efficiency.

Energy-Efficient Milling – Pneumatic double-ended roller mills minimize power consumption.

Centralized Automation – PLC/SCADA system ensures real-time monitoring and minimal labor.

Flexible Product Output – Supports multiple flour grades with precise blending.

Turnkey Engineering by Voson – From design, manufacturing, installation to after-sales service, Voson provides complete solutions for large-scale flour plants.

Flow chart of Wheat flour Mill Line

Fine Cleaning and Dust Control

The plant employs multiple destoners, magnetic separators, and aspirators arranged for parallel operation. Multi-point aspiration reduces dust spray-out while keeping the workshop environment clean. Voson’s design ensures even highly dirty wheat is processed effectively.

This is a complicated flow in 300tpd wheat flour milling plant, that can remove most of the coarse offal, middle size offal, and fine offal in the grain. The cleaning section is not only suitable for grain with lower moisture, but also the dirty grain.

Milling Section

Tempered wheat enters pneumatic roller mills with multiple break and reduction passages. Enclosed pneumatic transport maintains cleanliness and reduces energy loss. The design supports continuous high-capacity production while protecting flour quality.

The whole design will insure less bran is mixed into the bran and the flour yield is maximized. The whole mill material is transferred by a High-pressure fan. The milling room will be clean and sanitary.

Packaging Section

Automated bagging, bulk filling, and palletizing lines handle high-capacity output. Integrated weighing and inventory tracking optimize warehouse management.

The packaging machine is with sealed type bag-clamping mechanism, which can prevent material from leaking out. There are many types of specification like 1-5kg, 2.5-10kg, 20-25kg, 30-50kg. The clients can choose different packing specifications according to requirements.

Why Choose Voson for Large-Scale Wheat Flour Milling Equipment

With more than 20 years of experience in flour milling engineering, Voson has completed hundreds of turnkey projects across Asia, Africa, and South America. Our professional team ensures every plant is customized to local wheat varieties, market demand, and power conditions. Choosing Voson means choosing stability, efficiency, and international expertise.Get a Quick Inquiry