250TPD Wheat Flour Milling Project

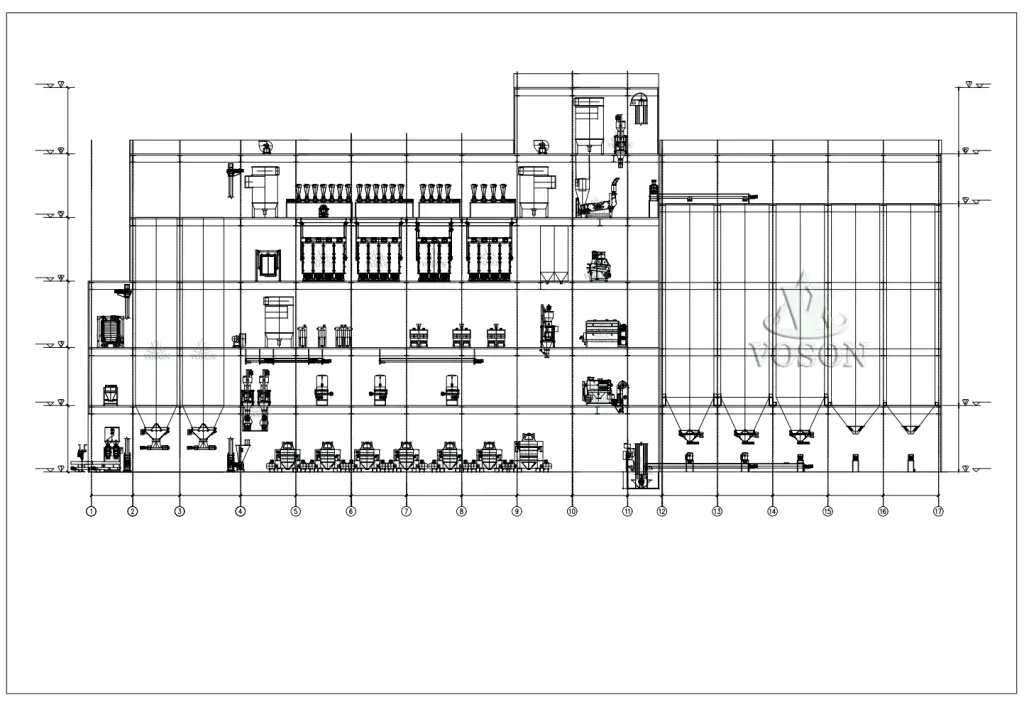

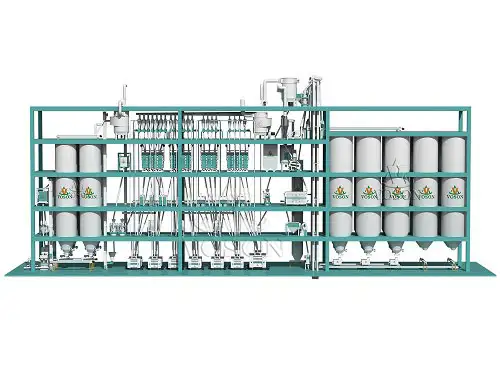

The 250TPD wheat flour milling project, designed and manufactured by Voson, represents one of the most advanced and large-scale flour processing solutions in the market today. This series of 250ton wheat flour mill is designed as a several-floor building, which is divided into the raw grain section, the grain cleaning section, the flour processing section, and the finished product packaging section; Pipes in the milling section are stainless steel, and the control system is PLC control.

Concrete structure building flour mill plant usually has three configuration design: four-story building, five-story building and six-story building. It can be determined according to the customer's requirements.Get Free Customize

Technical Parameters of Voson 250T Wheat Milling Equipment

| Production Capacity | Extraction Rate | Power Requirement | Land Area | Automation |

|---|---|---|---|---|

| 250 tons/day | 70–75% | 700–800 kWh/t | 4,500–5,200 m² | PLC/SCADA centralized control |

Key Features and Advantages of Voson Flour Milling Line

High Production Capacity – Designed for industrial-scale flour enterprises, ensuring continuous and stable supply.

International Standards – All equipment manufactured by Voson follows ISO and CE certifications.

Energy Efficiency – Advanced milling system reduces power consumption while maximizing yield.

Flexible Product Output – Supports multiple flour grades and market adaptability.

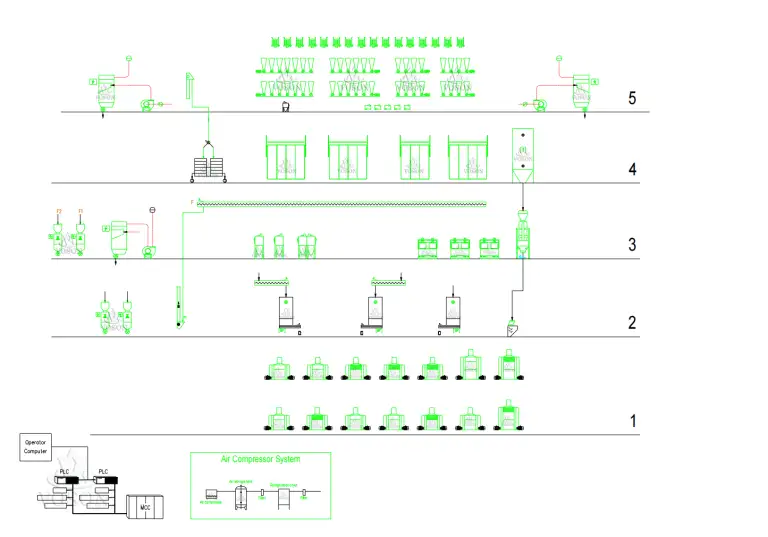

Centralized Automation – Smart PLC control allows real-time monitoring and minimizes labor requirements.

Turnkey Engineering – From design, production, and installation to after-sales service, Voson provides complete project solutions.

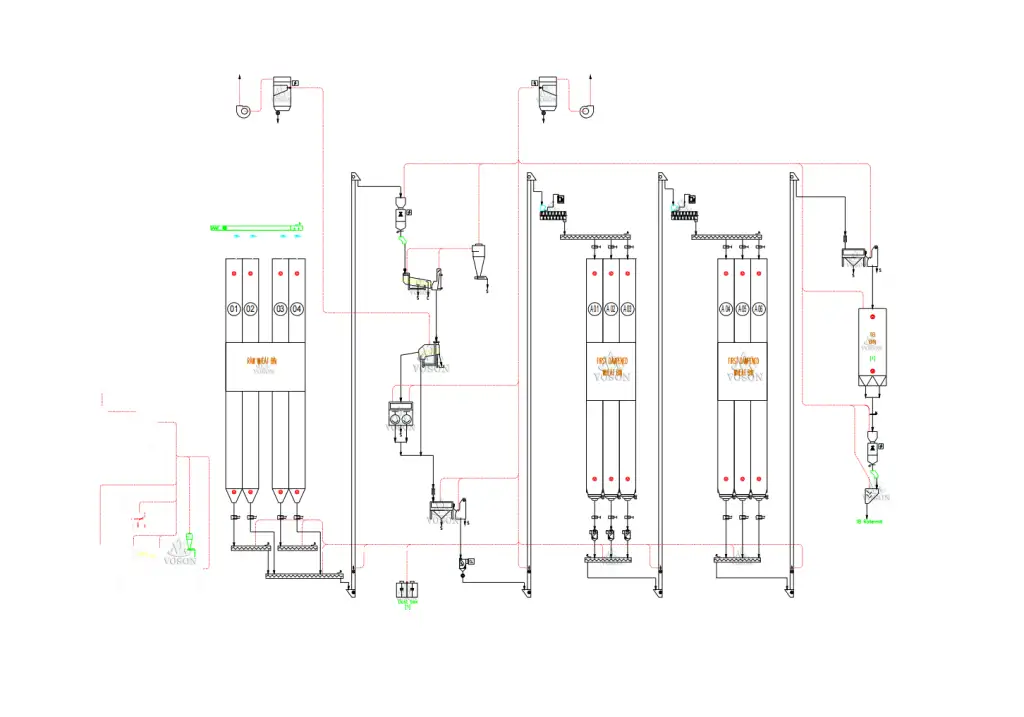

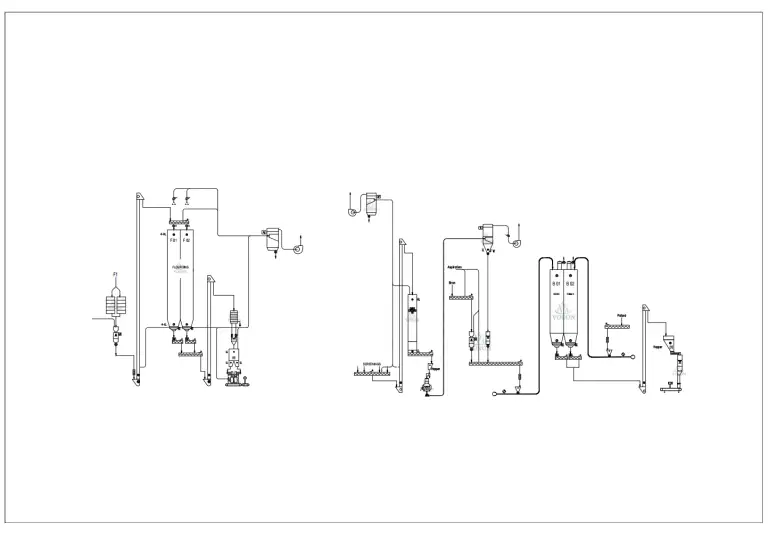

Flow chart of Wheat flour Mill Line

The 250TPD wheat flour milling plant supplied by Voson is designed with a complete and efficient process flow to ensure stable production, high flour yield, and international quality standards. The process is organized step by step as follows:

Pre-cleaning

Large impurities such as straw, stones, and oversized materials are removed by plane rotary vibrating screens and cylinder pre-cleaners to protect downstream equipment.

Fine Cleaning

The wheat passes through a series of cleaning machines, including vibrating cleaning screens, destoners, and magnetic separators, which efficiently remove small stones, sand, metal, and light impurities. Multiple aspiration systems are installed to reduce dust spray-out and maintain a clean working environment.Get Free Customize

Milling Section

The tempered wheat is ground by advanced pneumatic double-sided roller mills. The break, reduction, and sizing passages work step by step to gradually separate the bran, germ, and endosperm. Voson adopts energy-efficient roller mills with precise gap adjustment to ensure consistency.

Sifting and Purification

Flour is classified using high-capacity plansifters and purifiers. Fine flour passes through sieves, while larger particles are sent back for further grinding. Purifiers ensure the removal of bran specks and guarantee bright flour color.

Packing Section

Finished flour is packed into 1–50kg bags by automatic packing machines, with accurate weighing, sealing, and labeling. Bulk flour packing is also available depending on customer requirements.

All packaging machines are automatic. The packaging machine has advantages of high measuring accuracy, fast packing speed, reliable and stable working. The packing machine has the function of fault self-diagnosis. Its sewing machine has automatic sewing and cutting function.Get Free Customize

Why Choose Voson for Large-Scale Wheat Flour Milling Equipment

Pursuing suitable wheat flour milling machinery for your business is important. We have projects, and you can get advice and free craft designs from us.

With more than 20 years of experience in flour milling engineering, Voson has completed hundreds of turnkey projects across Asia, Africa, and South America. Our professional team ensures every plant is customized to local wheat varieties, market demand, and power conditions. Choosing Voson means choosing stability, efficiency, and international expertise.