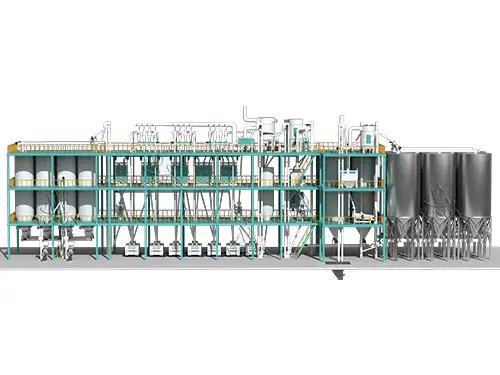

500TPD Maize Milling Project

The 500 tons per day maize milling project represents the highest capacity plant offered by Voson, designed to serve as a regional or national grain supply hub. This plant integrates state-of-the-art dry milling technology, fully automated control systems, and intelligent monitoring platforms to ensure stable, high-yield production. 500tpd maize milling plant, the project not only supplies daily consumption needs but also supports downstream industries such as food manufacturing, animal feed, and brewing.

This project by Voson is not just a large-capacity grain processing line, but a complete turnkey solution. From engineering design, equipment manufacturing, installation, and commissioning to staff training and after-sales support, Voson delivers the entire project package. With proven expertise in executing national and regional grain processing projects, this plant is designed to meet the demands of large-scale food supply chains with high efficiency and reliability.

Technical Parameters of 500TPD Maize Milling Line

| Parameter | Specification |

|---|---|

| Processing Capacity | 500 tons of maize per day |

| Raw Material | Maize / Corn kernels |

| Final Products | Maize flour (50–120 mesh), grits, bran |

| Extraction Rate | 75%–80% (depending on raw material quality) |

| Power Requirement | Approx. 1,500–1,800 kW |

| Plant Area & Operators | About 6,000–8,000 m², 25–30 operators |

This large-scale maize milling plant is widely adopted in Africa, Latin America, and Southeast Asia, where governments, grain reserve authorities, or leading food companies establish centralized plants to secure food supply. It is particularly suitable for regions with high maize consumption, where large-scale logistics and distribution systems support the continuous demand.

500TPD Maize Milling Plant Process Flow

500TPD Maize Milling Project process is based on a dry milling method, which guarantees consistent flour quality and minimal energy consumption.

1、Cleaning and Destoning

Raw maize is pre-cleaned using high-capacity vibrating cleaners and destoners to remove dust, stones, and impurities. The cleaning section is equipped with magnetic separators to eliminate metallic contaminants.

2、Dehulling and Degermination

Advanced dehullers and degerminators are applied to separate bran and germ efficiently. This step ensures flour whiteness and longer shelf life while securing high extraction rates.

3、Conditioning and Milling

Moisture conditioning improves kernel flexibility. High-strength roller mills then crush and grind the maize, achieving uniform granulation while preserving nutritional value.

4、Sifting and Grading

Large-capacity plansifters classify flour and grits into different mesh sizes. At this stage, by-products such as bran and germ are collected separately for feed or oil processing.

5、Blending, Fortification, and Packaging

Final flour is blended according to customer specifications and fortified with micronutrients if required by local food regulations. Fully automated packing lines allow both bulk and retail packaging.

Types of Maize Flour Produced by Mesh Size

60–80 mesh fine maize flour – for bread, biscuits, noodles, and instant foods.

40–60 mesh medium maize flour – for porridge, chapati, tortillas, and household cooking.

20–40 mesh coarse grits – for beer brewing, snack food, and breakfast cereals.

Bran and germ by-products – for animal feed or oil extraction.

Key Advantages of 500TPD Corn Milling Project

National-level production scale, ensuring stable grain supply to millions of consumers.

High automation and intelligent operation, reducing manpower while improving efficiency.

Energy-efficient design, optimized for long-term operation and reduced costs.

Flexible product output, meeting both household and industrial requirements.

Turnkey service by Voson, including design, installation, commissioning, and training.

China Maize Milling Plant Manufacturer

Voson has decades of engineering experience in building maize milling lines ranging from 20TPD to 500TPD. With more than 50 successful projects worldwide, Voson is trusted for its robust equipment, reliable service, and customized engineering solutions. From initial design to after-sales support, Voson ensures every project operates with high efficiency and market competitiveness.