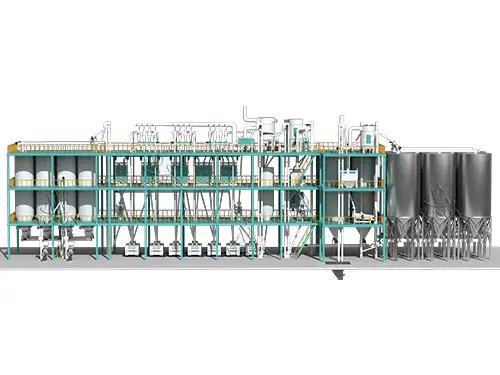

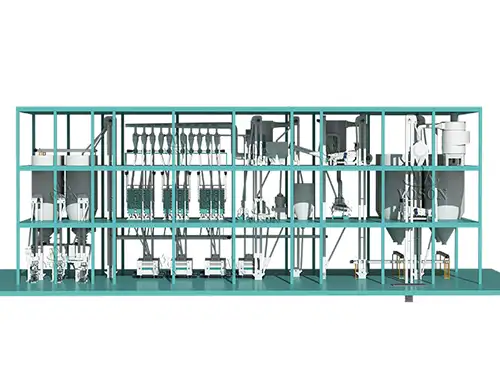

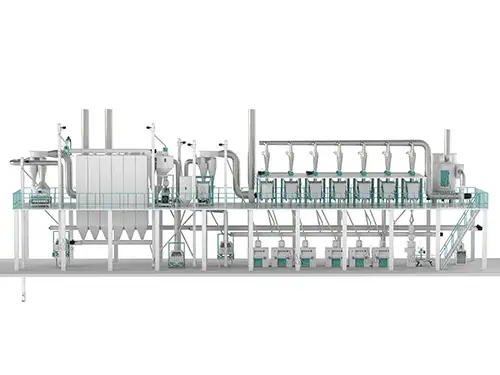

Grain Cleaning

The cleaning step is crucial in maize milling. Henan Voson Machinery's advanced aspiration systems reduce dust. They effectively remove various impurities from maize. The systems suit both low - moisture and dirty maize, ensuring only clean maize proceeds to milling. Voson's technology ensures good impurity removal for better milling and product quality.

- Thoroughness

- Fine Screening

- Efficiency

- Quality Assurance