Rapeseed (Canola) Oil Production Project

Voson Machinery provides turnkey rapeseed oil production line, combining advanced engineering and decades of project experience. From seed cleaning to final refining and packaging, Voson designs plants that deliver high oil yield, stable operation, and consistent product quality. Rapeseed oil is widely valued for its light taste and balanced fatty acid profile, making it a popular edible oil worldwide.

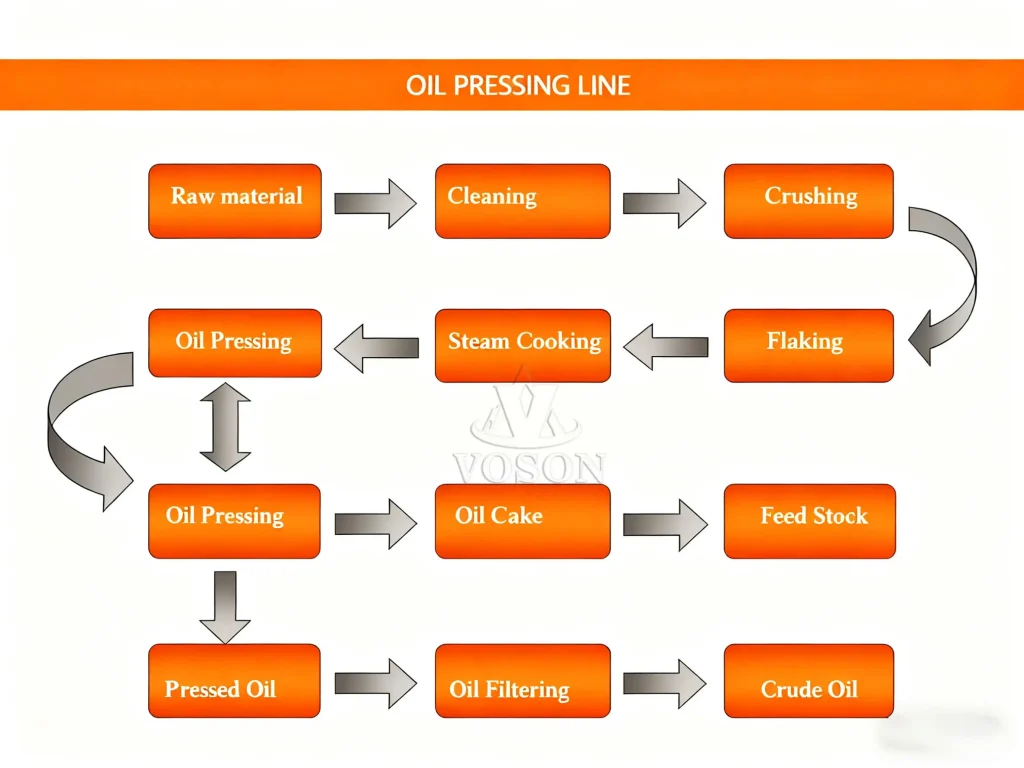

Process Flow of Rapeseed Oil Production Line

Seed Cleaning and Dehulling

Raw rapeseeds are cleaned to remove dust, stones, and impurities. Dehulling separates the outer shell from the kernel, reducing fiber content and improving oil extraction efficiency.

Crushing and Flaking

Dehulled seeds are crushed into small particles and flaked into thin sheets to enhance oil release during extraction.

Cooking and Conditioning

Flakes are heated under controlled temperature and moisture conditions to optimize oil recovery.

Oil Extraction

Mechanical pressing or solvent extraction is applied depending on the plant scale. Solvent extraction is preferred for large-capacity lines to achieve maximum oil recovery.

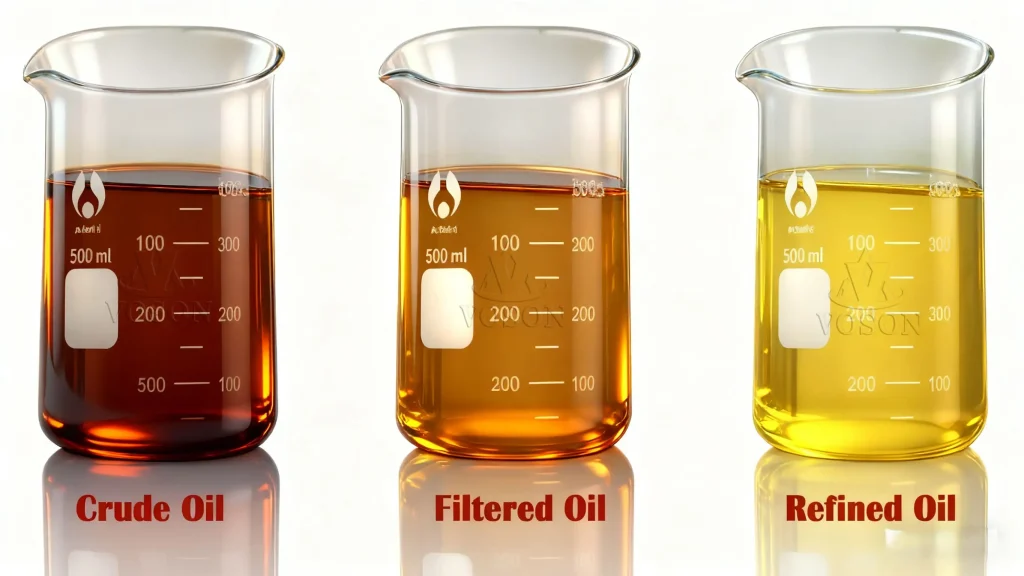

Filtration and Refining

Crude oil is filtered to remove solid residues and then refined through degumming, neutralization, bleaching, and deodorization. Voson uses plate frame or leaf filters for high efficiency.

Packaging

Refined rapeseed oil is stored in stainless steel tanks and packaged into bottles, drums, or pouches according to market demand.

Technical Parameters (Example: 100TPD Rapeseed Oil Plant)

| Item | Specification |

|---|---|

| Processing Capacity | 100 tons/day rapeseeds |

| Oil Yield | 38–42% |

| Residual Oil in Meal | ≤1% after solvent extraction |

| Power Consumption | 45–60 kWh per ton of raw material |

| Steam Consumption | 260–300 kg per ton of raw material |

Voson rapeseed oil production lines are particularly suitable for regions with abundant rapeseed supply, such as Eastern Europe (Ukraine, Romania), Central Europe (Germany, Poland), Central Asia (Kazakhstan), and parts of China. Our engineering team has extensive experience in building turnkey rapeseed oil plants, providing tailored solutions for local conditions, including raw material quality, energy availability, and workforce skills.

Key Advantages of Voson Rapeseed Oil Projects

Flexible Capacity Options – Voson provides lines from 30 TPD to over 1,000 TPD.

Adaptable to Local Raw Materials – Can handle varying seed qualities, moisture levels, and impurity content.

Energy-efficient & Automated – Optimized for low power consumption with high automation.

Suitable for Multiple Regions – Ideal for Europe, Asia, and Africa, where rapeseed is widely cultivated.

Turnkey Project Support – Complete engineering, equipment supply, installation, and staff training.