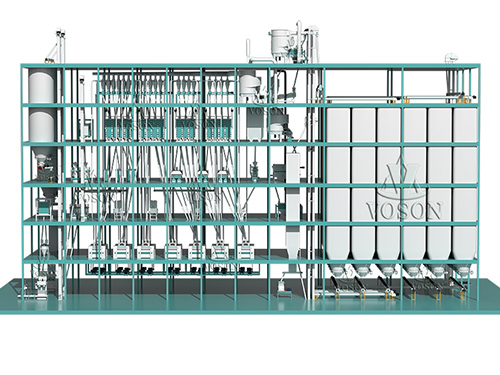

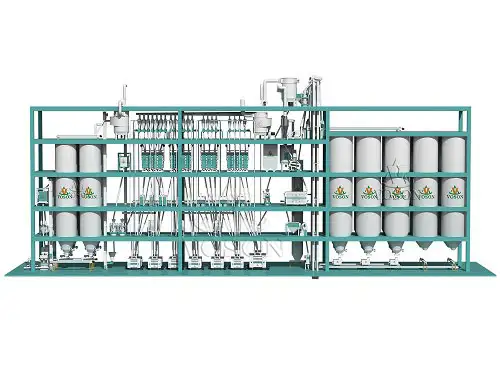

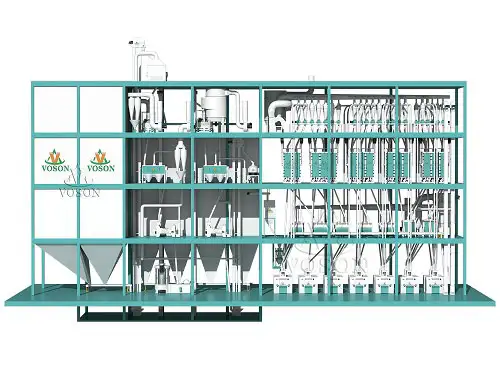

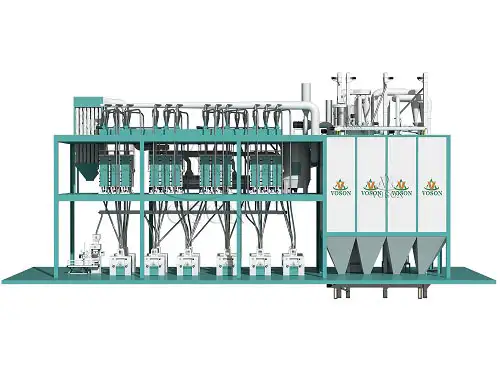

Grain Cleaning

The cleaning section is the first and crucial step in wheat milling. Henan Voson Machinery uses advanced aspiration systems to reduce dust. It effectively removes various impurities from wheat. This section can handle different types of wheat, ensuring clean and contaminant - free grain for the next stage.

- Thoroughness

- Fine Screening

- Efficiency

- Quality Assurance